I contributed to the development of a predictive maintenance and real-time monitoring system that analyzes machine health by collecting and visualizing vibration, temperature, and sound data. The project was designed to predict potential failures, generate instant alerts, and track faults, ultimately improving operational efficiency and minimizing downtime.

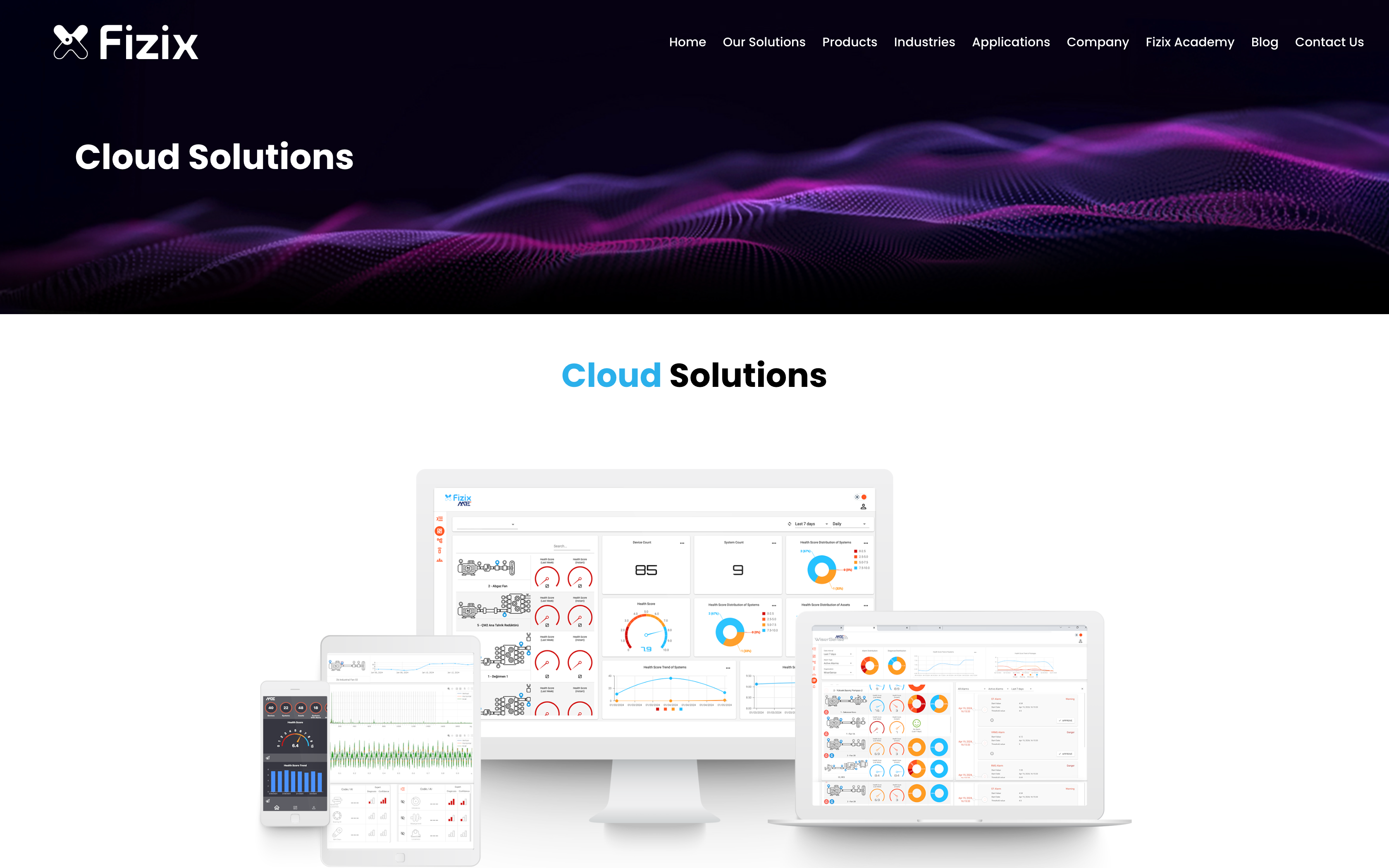

The frontend featured interactive dashboards built with jQuery, enabling users to monitor real-time sensor data and historical trends through dynamic visualizations. DevExpress reports were integrated to provide in-depth insights into machine performance and failure patterns.

On the backend, .NET-powered solutions ensured seamless data processing, real-time event handling, and API integrations. Continuous analysis of sensor data allowed the system to detect anomalies and trigger immediate warnings, helping maintenance teams take proactive measures before critical failures occurred.

By combining predictive analytics, real-time monitoring, and automated reporting, the system significantly improved machine reliability, optimized maintenance processes, and reduced overall costs.